TYPES OF BELLOW EXPANSION JOINTS

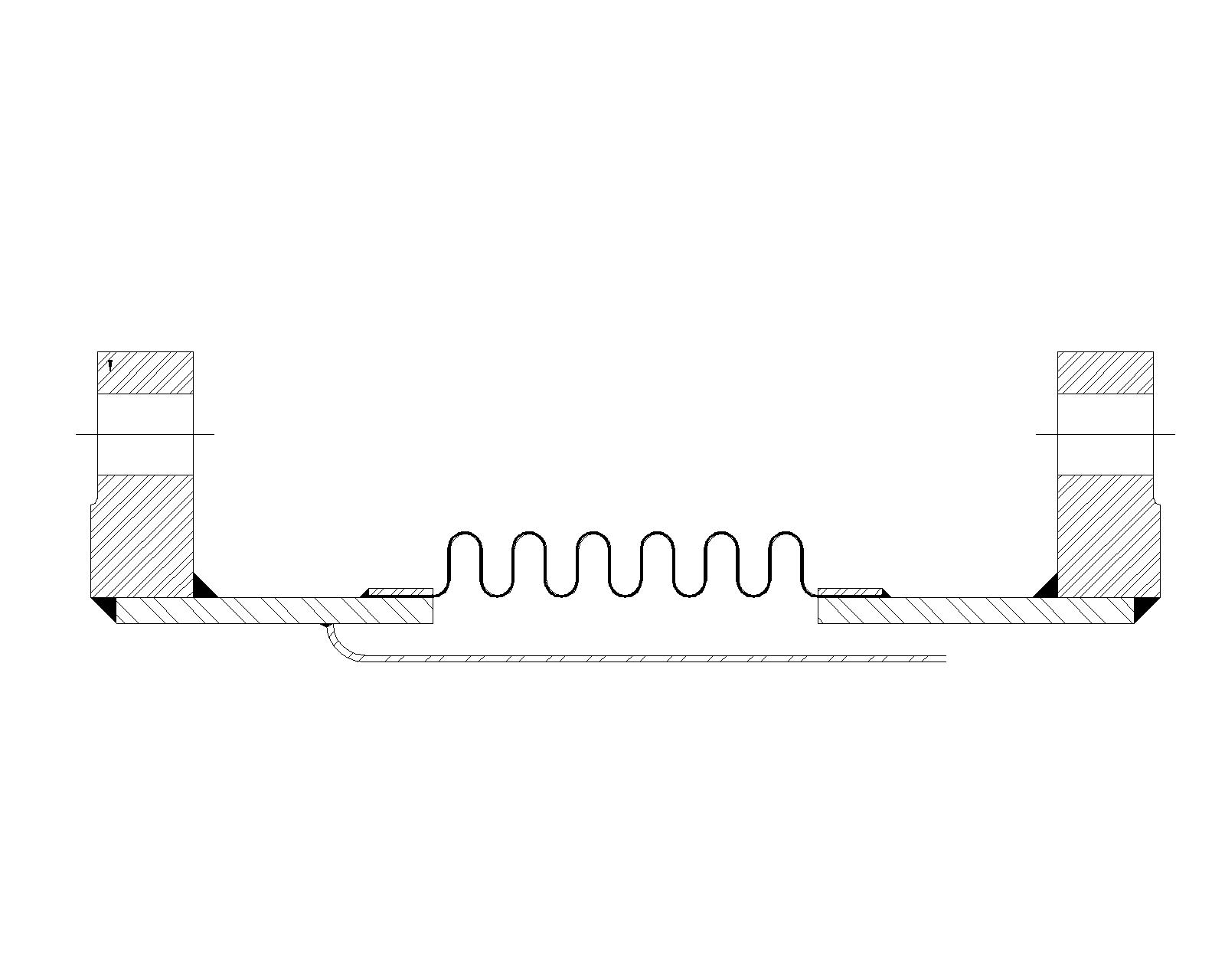

Axial Expansion Joint

They are the simplest form of Expansion Joint and usually considered as a first choice for any application due to its economic offerings. It consists of a bellow element with end connections. It is used for axial movement only in pipe configurations. However, it can also absorb small amounts of other two types of basic movements viz. lateral and angular.

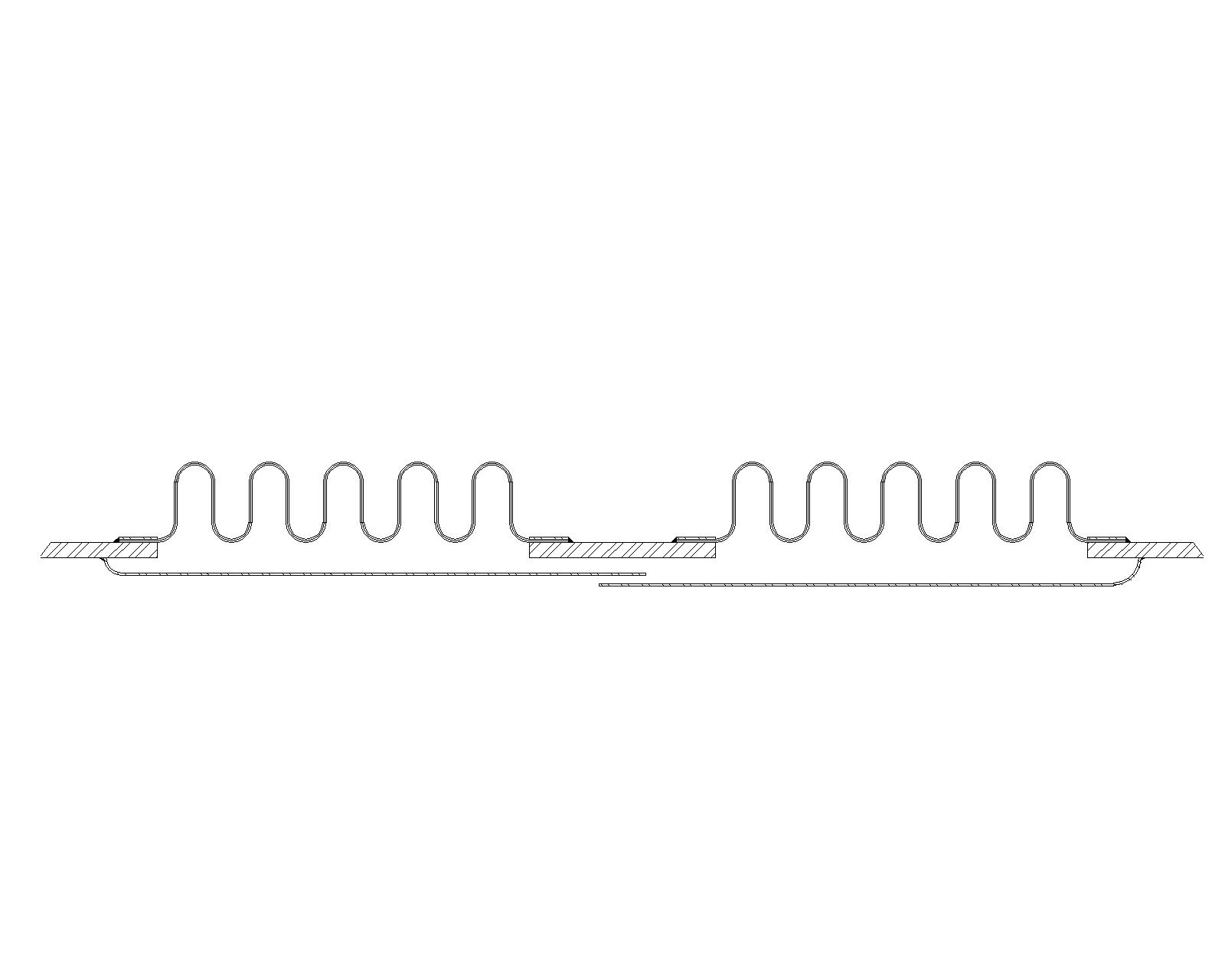

Universal Expansion Joint

Two bellows connected by a common connector or centre piece, is called Universal expansion joint. Although it can absorb combination of all three movements they are generally used to absorb large amount of lateral deflections. Double expansion joint is different from Universal expansion joint. A double pipe expansion joint consists of two bellows joined by a common connector which is anchored to some rigid part on the installation by means of an anchor base. Each bellows acts as a single pipe expansion joint and absorbs the movement of the pipe section in which it is installed, independently of the other bellows.

Hinged Expansion Joint

Hinged Expansion Bellows are designed to absorb angular deflection in one plane by use of pins and hinge plates. The hinge pins, hinge plates are designed to restrain pressure thrust. Some HEJ can be provided with a slot in the hinge plate to accommodate a little amount of axial movement; however it demands the use of properly designed anchors and guides as such hinge plates are not capable of restraining the pressure thrust.. Hinged Expansion Bellows should be used in sets of 2 or 3 to function properly. It can also be designed and supplied as a Universal Hinged Expansion Joint by use of a universal bellow element.

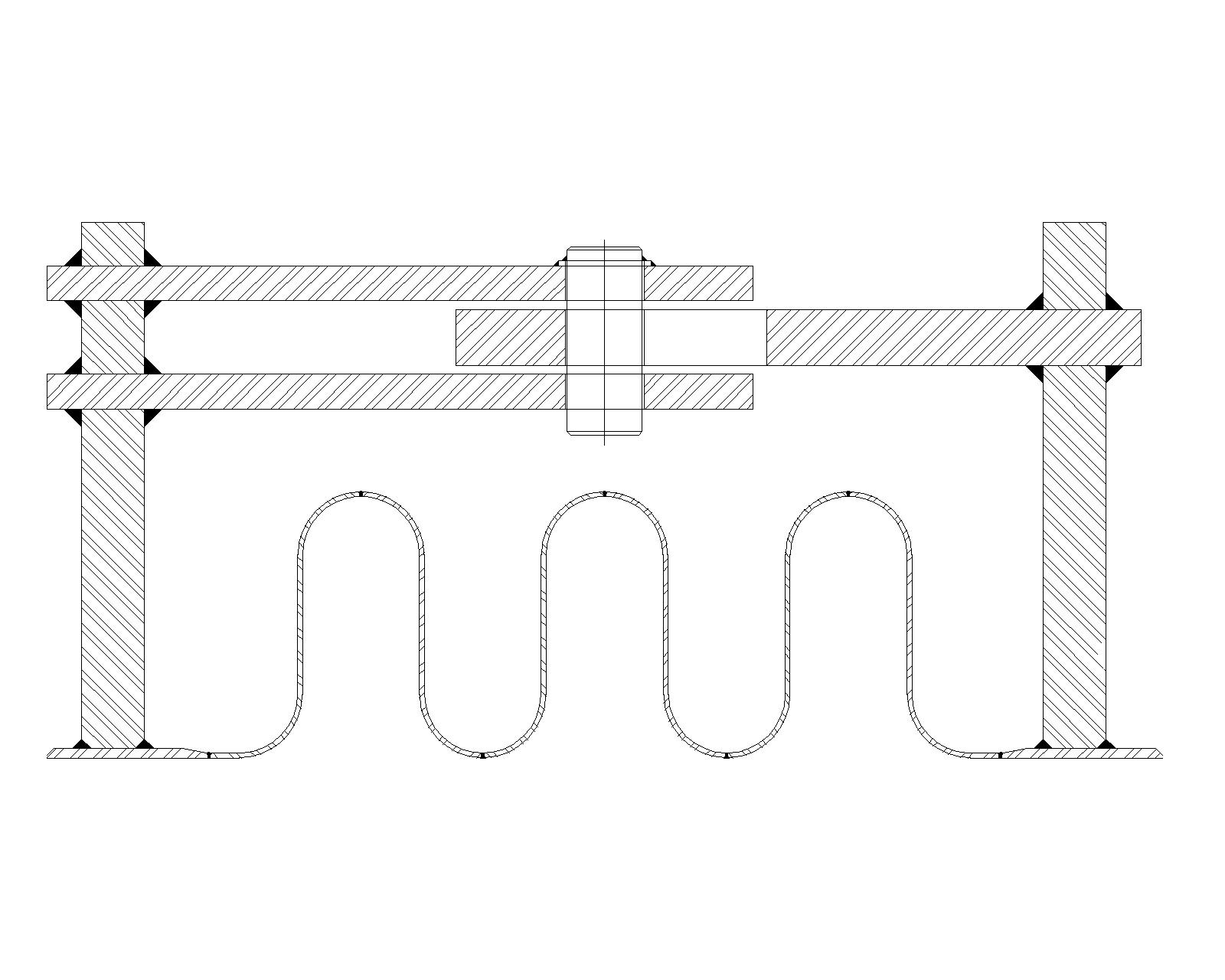

Gimbal Expansion Joint

A Gimbal Expansion Joint is designed to permit angular rotation in any plane by the use of 2 pairs of hinges affixed to a common floating gimbal ring. It is designed to restrain pressure thrust so that the thrust is not transferred to the pipe anchors. Again it can be designed and supplied as a double Gimbal Expansion Joint.

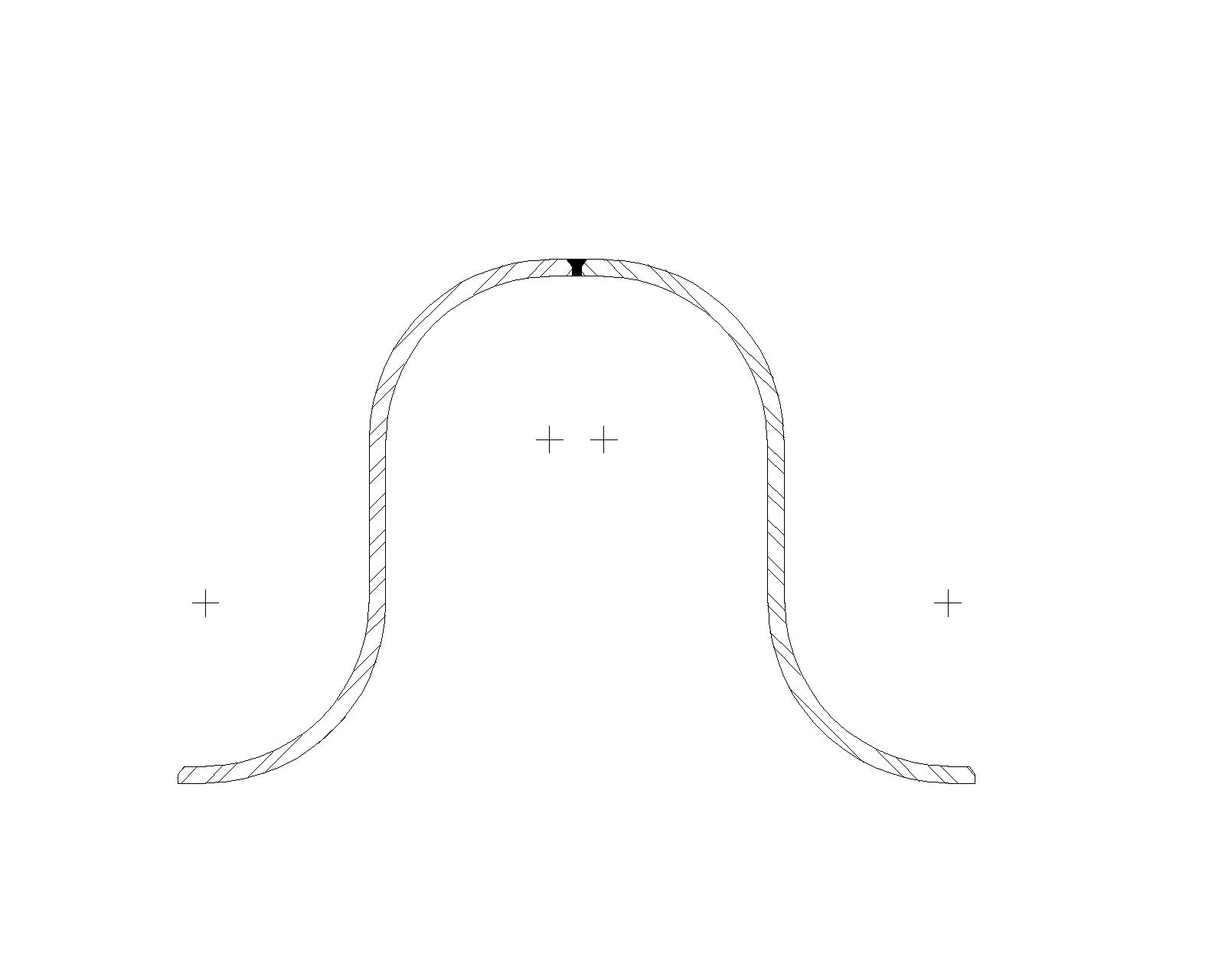

Flanged and Flued Expansion Joint

A thick walled Bellow made in two halves from flat annular plates. The outside edge of the plate are formed in one direction (flanged) and the inside edge are formed in the other direction (flued); the two halves are then welded together to form a convolution. They usually finds application in heat exchangers, welded to the shell to accommodate the thermal movement due to the temperature difference between shell and tube bundles.

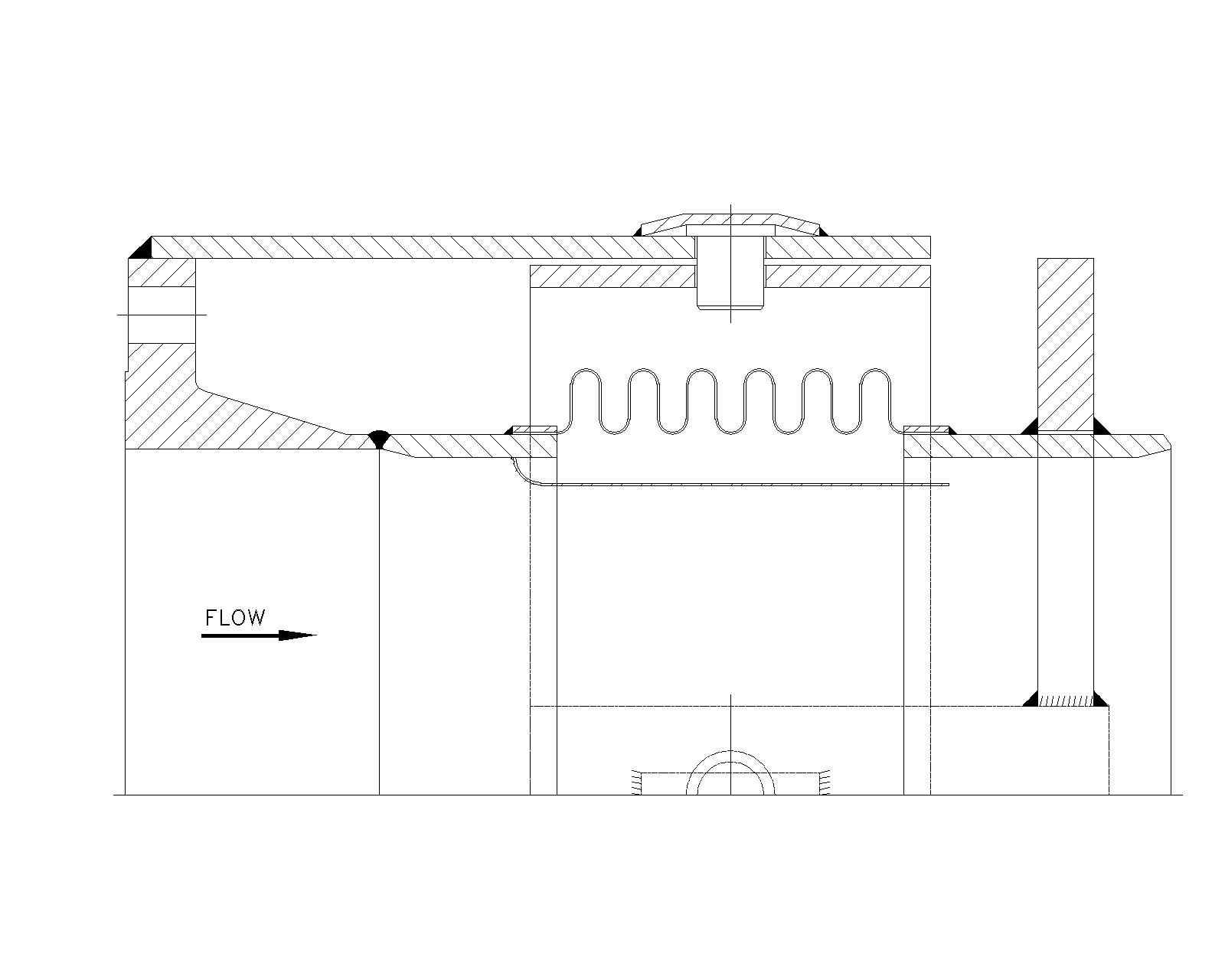

Pressure Balance Bellow Expansion Joint

A Pressure Balance Expansion Joint can accommodate axial and lateral movements and also restrain the pressure thrust; hence relieving the anchors and piping of the load and can be fitted in a limited space. They can be supplied with configurations namely Inline Pressure balance and Elbow type Pressure balance Expansion Joints.

An Inline Pressure Balance expansion joint consist of two line bellows and a balancing bellow having effective area twice than that of line bellows. The line bellows absorb the axial and/or lateral movement while restraining the pressure thrust by the means of the tie devices interconnecting the balancing bellow, which is also subjected to the line pressure. Each bellows are designed to absorb the axial movement while the line bellows are designed to absorb the lateral deflections also.

An Inline pressure balance expansion joint is designed to absorb axial, lateral and angular deflection, while restraining the pressure thrust exerted by the internal pressure and without a change in direction of the piping. The pressure thrust is restrained by the tie rods arrangement, which connects the line bellows and the balancing bellows. It is a constant volume system, so the Main Anchors can be designed as intermediate anchors, and function only to direct the thermal expansion of the pipe towards the expansion joint.

Elbow type expansion joint consists of a balancing bellows and one/two line bellows. The balancing bellows is subjected to axial deflection only, while the line bellows absorbs lateral and/or axial deflections. This type of expansion joint is also a constant volume system. These bellows can be also used at the bends of the piping or change in direction of piping, where adequate support or main anchors is not possible.

Rectangular Expansion Joints

Most commonly used in low pressure piping to absorb thermal movements and vibration absorber in short runs adjacent to fans, blowers and other mechanical equipments. Can be designed to accommodate a combination of axial and lateral movements; to accommodate a large amount of lateral movement double bellow arrangement can be utilized. We can manufacture rectangular expansion joint having no size limitation. These type of expansion joint are provided with various configuration of corners viz. round, single miter, double miter and camera corners.